Back in September of this year I completed a big turbo build with a recirc setup. It was even turned by Torrie at Unleashed turning who is a pretty well known ST turner and he can confirm it’s a recirculating big turbo.

In my last turbo post I talked about the build itself. Now I want to focus on the recirc system itself. It’s not an off the shelf solution but it could easily be made into one. It was a custom one off system but even still it can be done. Not just done but done correctly and fairly easily.

Part of the issue some people are saying that it’s going to be difficult to do a recirc setup is, because the external BOV is located under the oil pan. While that’s true you can move things in the engine bay around quite a bit. There is plenty of room behind the engine and it’s very easy to route some piping to move how things fit.

Okay lets take a look at some picture on how you can do this properly.

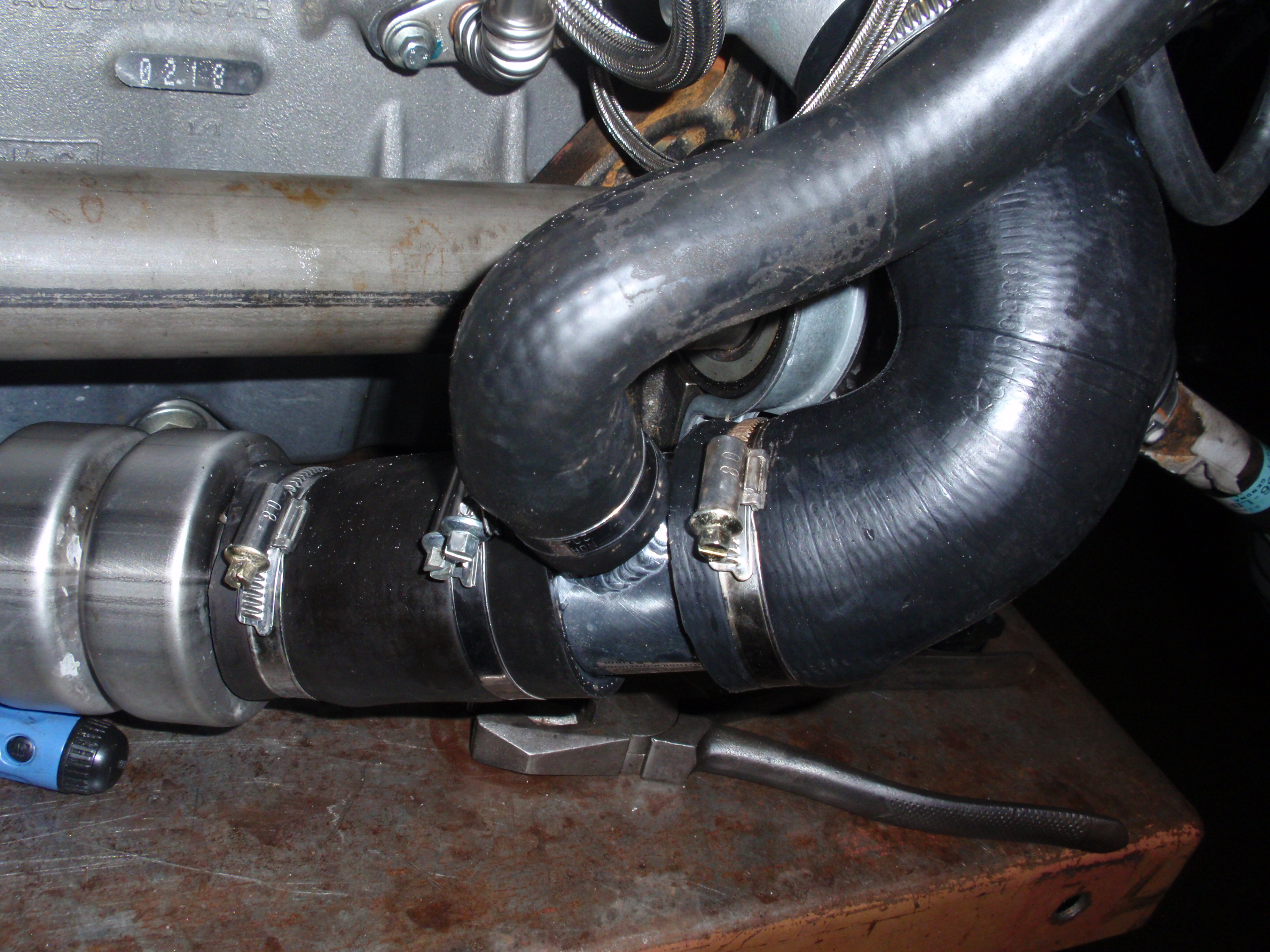

This first picture is the heart of the recirc setup. You’ll notice we just have a tee pipe that splits where the air goes. This allows when the pressure (for lack of a better term) to be diverted to the recirc valve which will allow the excess air to be routed back into the intake stream.

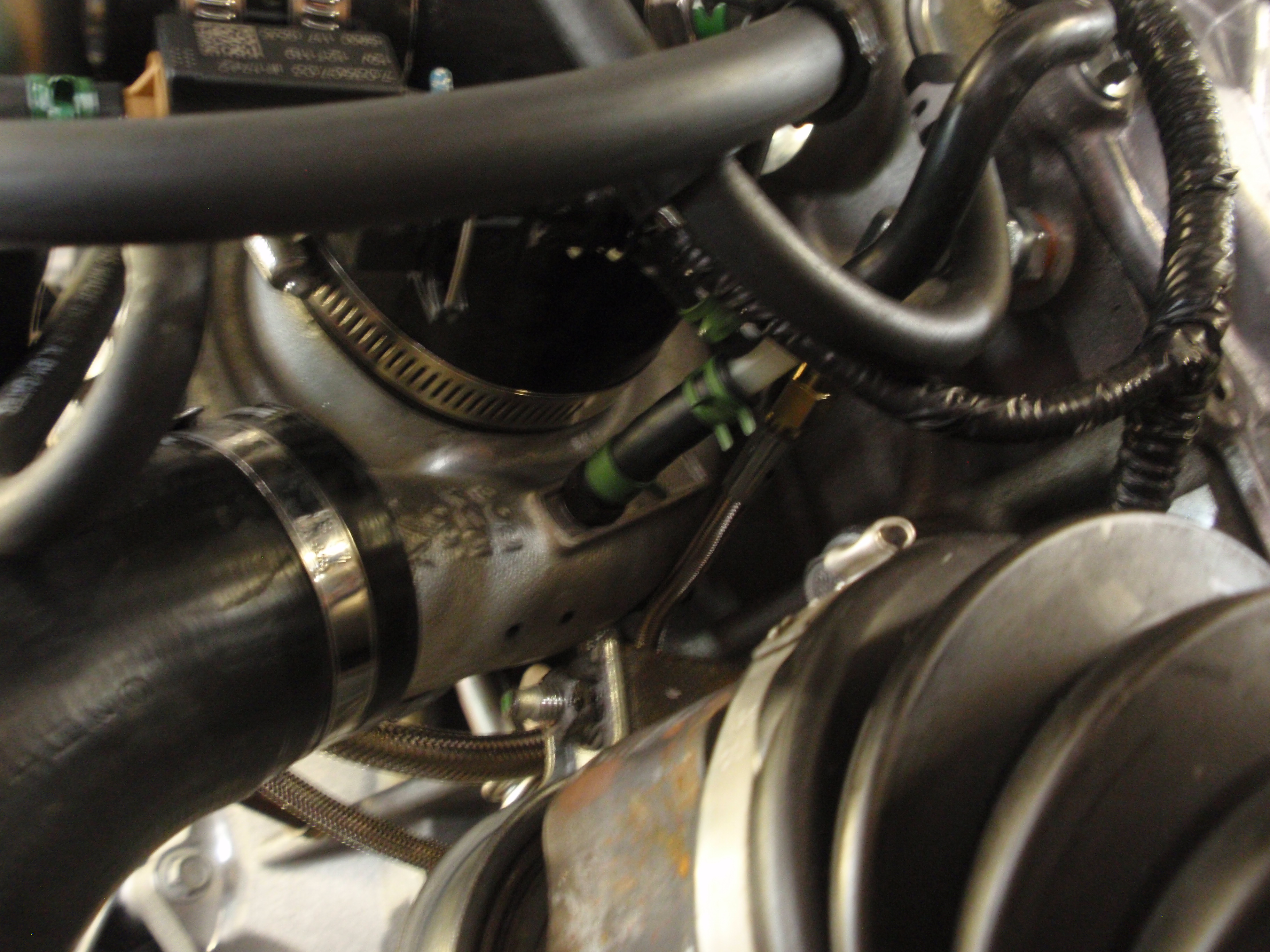

This next picture is the recirc valve itself. It’s actually a dual vale and can have a “horn” put on to make it into an annoying BOV that makes that pssst sound. The piping from the first picture that goes upward is the pipe that connects to this valve. as you can see it’s not under the oil pan it’s beside the turbo itself.

This is it.

It’s not a great picture but that’s the recirc valve I used. The details are 1" (25mm) Inlet & Outlet Turbo BOV Blow off Value DV Buypass A4 S4 Golf 1.8T S. There is a listing for it on ebay for under $40 USD.

Specs of the valve are T6061 Aluminum Body and Cover, Solid Brass valve, 1" (25mm) Inlet & Outlet, Fast Respond, Incredible Sound, Operational 6 to 28 PSI. The incredible sound I don’t much care about because I’m using it DV so I don’t hear it and 6-28 PSI, well my GT2860RS is tuned for 22 PSI max.

The valve is both mechanical and computer controlled. It has interchangeable springs if you need it to open more or less and has a nice long metal screw that allows for fine adjustment.

You’ll notice it was placed facing angled upward and high on the back of the engine. This is so you can take the engine cover off and reach down with an allen wrench to fine tune it as you see necessary. The goal was easy access so you don’t have to keep taking the under side of the car off and lifting it up while tuning.

This where things got tricky. The turbo piping doesn’t have a fitting meaning we can’t just connect the valve to the intake system directly. This had to be modified. You’ll notice the two brackets holding it on. The intake had to be modified to allow this to be added. The shop (Chuck) that did the work on making it recirculate didn’t say if he had to fabricate a new piece but he made it sound like he was able to modify the existing piece.

That’s pretty much it for setting up a big turbo Focus ST for recirculation (or using a Diverter Valve).

Last two pictures are a bit blurry and were hard to get but I think they’re the right ones… One major thing that comes up is where to measure boost. A lost of people will put an external boost tap on one of the pipes. Typically 90 degree pipe. I didn’t do that and instead taped it into the compressor housing directly.

There are two reason I recommend directly tapping into the housing. 1) You get the best reading because it’s taken directly from the turbo. 2) Pipes bend and flex so you may get some loss and misreads.

Inlet Clamp

Added Dec 15, 2014

BADWOLF on FosusST.org commented that the inlet tube isn’t quite long enough to reach the intake on the turbo. I ran into this same issue. The real solution is to get a longer silicon tube. It’s better to be longer than you need and cut it down. However, the tube we had was able to fit. Personally I’m not concerned about the tube itself. The real issue in my opinion is if you look at the pictures above you’ll see we went with some pretty small (standard) clamps to hold it on.

While the tube is fine the clamps were not. I had the hose blow off during some spirited driving. There was no damage at all. Just a tube came loose. For anyone out there that this happens to the car doesn’t / didn’t go into limp mode. It drove as is it was a normal focus without a turbo. I wouldn’t recommend driving it very far though until you can get the tube reconnected.

A friend of mine came over to help me get the tube back one since I didn’t have the physical strength to push it on while under the car held up with jack stands. He’s been tuning longer than I have so I trust his judgment. He realigned the tubing on both sides and used the massive claps you see on in the picture above on both sides of the tube. So far under the same conditions the tube is holding just fine.

I also want to add that there was minimal blowby in the inlet. This is to be expected and as long as you don’t have a massive amount of oil it’s nothing to worry about. You don’t need an oil catch can. This is a normal part of a turbo setup.